Vacuum Half Nipple-one Flange Rotatable Vacuum CF nipple Flanges Fittings SS304 Wholesale

Item specifics

- Brand

- RUIJIA

- Size

- CF16-CF200

- Material

- SS304, SS316L

- Seal material

- Oxygen free copper, silver plated copper

- Temperature

- -200~800℃

- Packing

- sealed plastic bag with a protective plastic cap.

Review

Description

Vacuum Half Nipple-one Flange Rotatable Vacuum CF nipple Flanges Fittings SS304 Wholesale feature

CF vacuum nipple rotatable are mainly used in ultra-high vacuum systems, A series of tests are required before shipment, including vacuum sealing testing, dimensional accuracy testing, etc., to ensure the quality and performance of the joints.

The packaging before shipment usually uses anti-static packaging to protect the joints from static electricity damage.

When assembled and used, CF vacuum half nipple are usually connected by metal sealing to ensure the vacuum degree and sealing of the system.

Vacuum Half Nipple-one Flange Rotatable Vacuum CF nipple Flanges Fittings SS304 Wholesale specifications

|

Product Name

|

Vacuum Half Nipple-one Flange Rotatable Vacuum CF nipple Flanges Fittings SS304 Wholesale

|

||

Brand | RUIJIA | ||

Size | CF16-CF200 | ||

Material | SS304, SS316L | ||

Seal material | Oxygen free copper, silver plated copper | ||

Standard | CF Standard | ||

Temperature | -200~800 | ||

Working Pressure | Vacuum~atmosphere pressure | ||

|

Helium Leak Test

|

1×10 -9 Pa・m³/sec or less

|

||

|

Packing

|

sealed plastic bag with a protective plastic cap.

|

||

|

Surface

|

Sand Blasting or Polished Surface

|

||

Product parameters

Vacuum Half Nipple-one Flange Rotatable Vacuum CF nipple Flanges Fittings SS304 Wholesale Unit:mm

| Model No. | Material | A | B | C |

| CF16NR | S.S.304 | 33.8 | 76 | 19.05 |

| CF35NR | S.S.304 | 69.5 | 126 | 38.1 |

| CF63NR | S.S.304 | 113.6 | 210 | 63.5 |

| CF100NR | S.S.304 | 151.6 | 270 | 101.6 |

| CF150NR | S.S.304 | 202.5 | 334 | 152.4 |

| CF200NR | S.S.304 | 253.2 | 334 | 203.2 |

Special Sizes Available Upon Request.

Assembly Instructions for CF Flanges

1.Apply a small amount of high temperature anti-seize compound to the bolt threads.

2. Check that both flange surfaces are clean and sealing edges are free from nicks and scratches.

3. Using clean, lint free gloves, unpack gasket.

4. Place gasket in the knife edege counterbore of nonrotatable flange.

5. Align the mating hole pattern and leak test grooves.

6. Install the proper bolts and tighten had tight. Check to see that the flange faces are parallel.

7. Tighten the bolts 1/4 to 1/2 turns using a star pattern until the flange faces are metal to metal.

Production Center

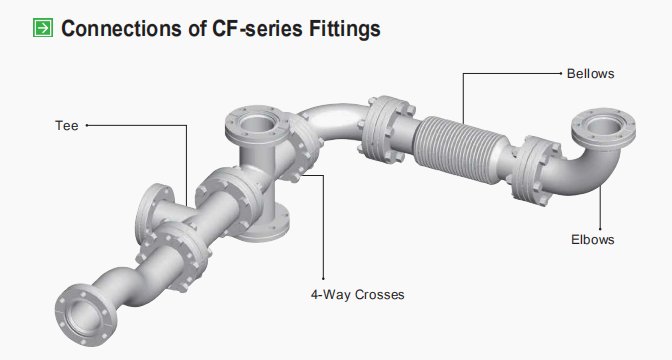

Application