What Is It like to Vacuum Flanges Specification, Maintenance, And Usage?

- Share

- Issue Time

- Feb 8,2024

Summary

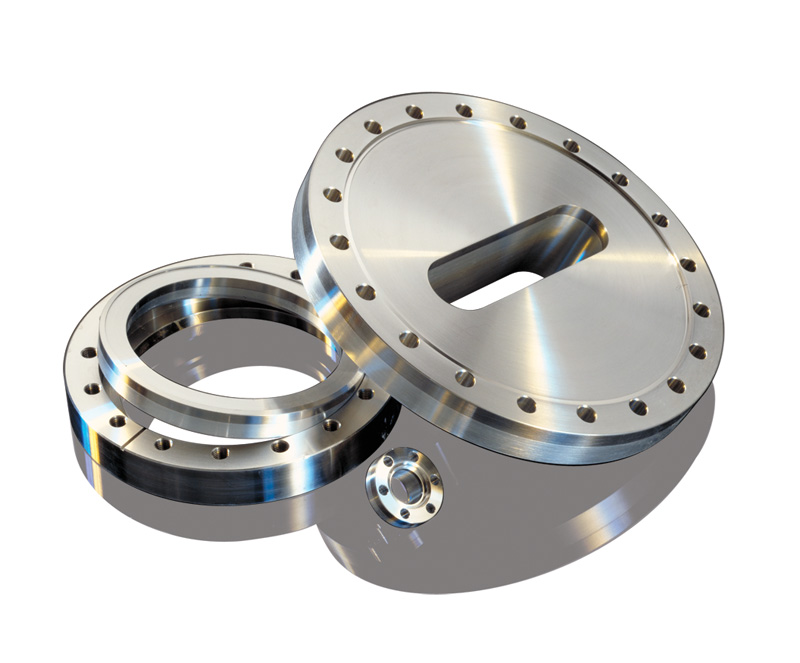

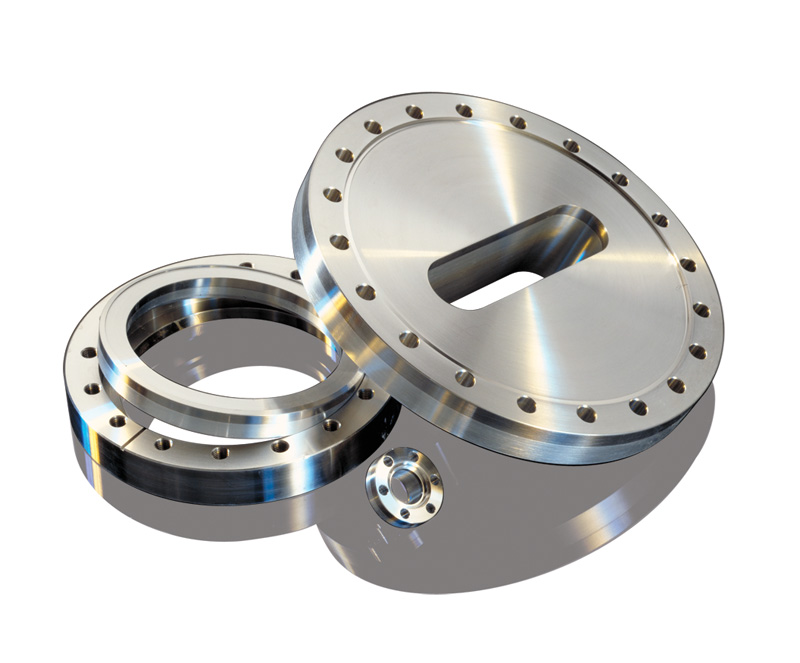

Vacuum flanges are an essential component in vacuum systems, used to connect various vacuum chambers, pumps, and other vacuum components. Here is some information about their specification, maintenance, and usage:

Vacuum flanges are an essential component in vacuum systems, used to connect various vacuum chambers, pumps, and other vacuum components. Here is some information about their specification, maintenance, and usage:

1. Specification:

- Material: Vacuum flanges are typically made from stainless steel, aluminum, or other materials with high vacuum compatibility.

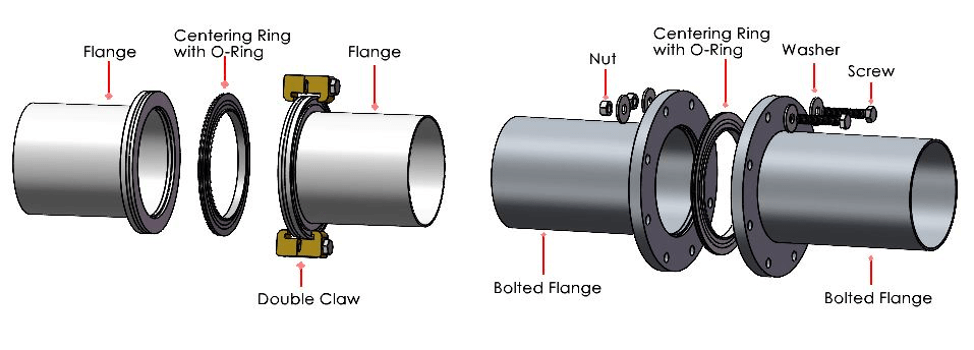

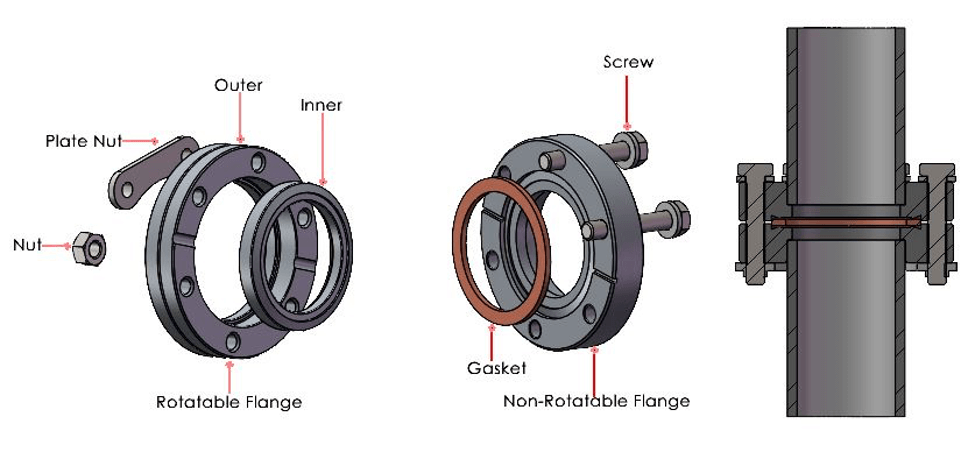

- Size: Flanges come in various sizes, such as NW (ISO-KF) flanges ranging from NW10 to NW50, CF (ConFlat) flanges ranging from CF16 to CF350, and ISO flanges ranging from ISO63 to ISO500.

- Vacuum level: Flanges are designed to withstand specific vacuum levels, so it is important to choose the appropriate flange based on the required vacuum level of your system.

- Sealing method: Flanges can have different sealing methods, such as elastomer o-rings, metal seals, or copper gaskets. The choice depends on the application and vacuum requirements.

2. Maintenance:

- Regular inspection: Check the flanges for any signs of damage, corrosion, or wear. Replace any damaged or worn-out flanges.

- Cleaning: Clean the flanges regularly to remove any dirt, dust, or contaminants that may affect the vacuum integrity. Use appropriate cleaning solutions and techniques recommended for the specific material of the flanges.

- O-ring/gasket replacement: If using elastomer o-rings or gaskets, periodically inspect and replace them to ensure proper sealing.

3. Usage:

- Installation: Ensure that the flanges are properly aligned and tightened using appropriate torque values. Follow the manufacturer's instructions for installation.

- Leak testing: Before operating the vacuum system, perform a leak test to ensure that the flanges are properly sealed. Use a suitable leak detector or method to identify any leaks and fix them before proceeding.

- Operating conditions: Follow the recommended operating conditions provided by the manufacturer, such as maximum pressure, temperature limits, and compatibility with gases or chemicals used in the system.

- Handling: Avoid excessive force or impact on the flanges, as this can cause damage. Use proper tools and techniques when handling or manipulating the flanges.