How to assemble and use CF Flanges System?

- Share

- Issue Time

- Dec 4,2024

Summary

We are the manufacturer of CF Flange Fittings,The article introduce regarding how to assemble and use CF Flanges System, Also introduces CF Flanges System includes which components,if you have any requirement about the CF Flanges assemblies, pls let us know, we will do our best to help you.

What’s CF Flange system?

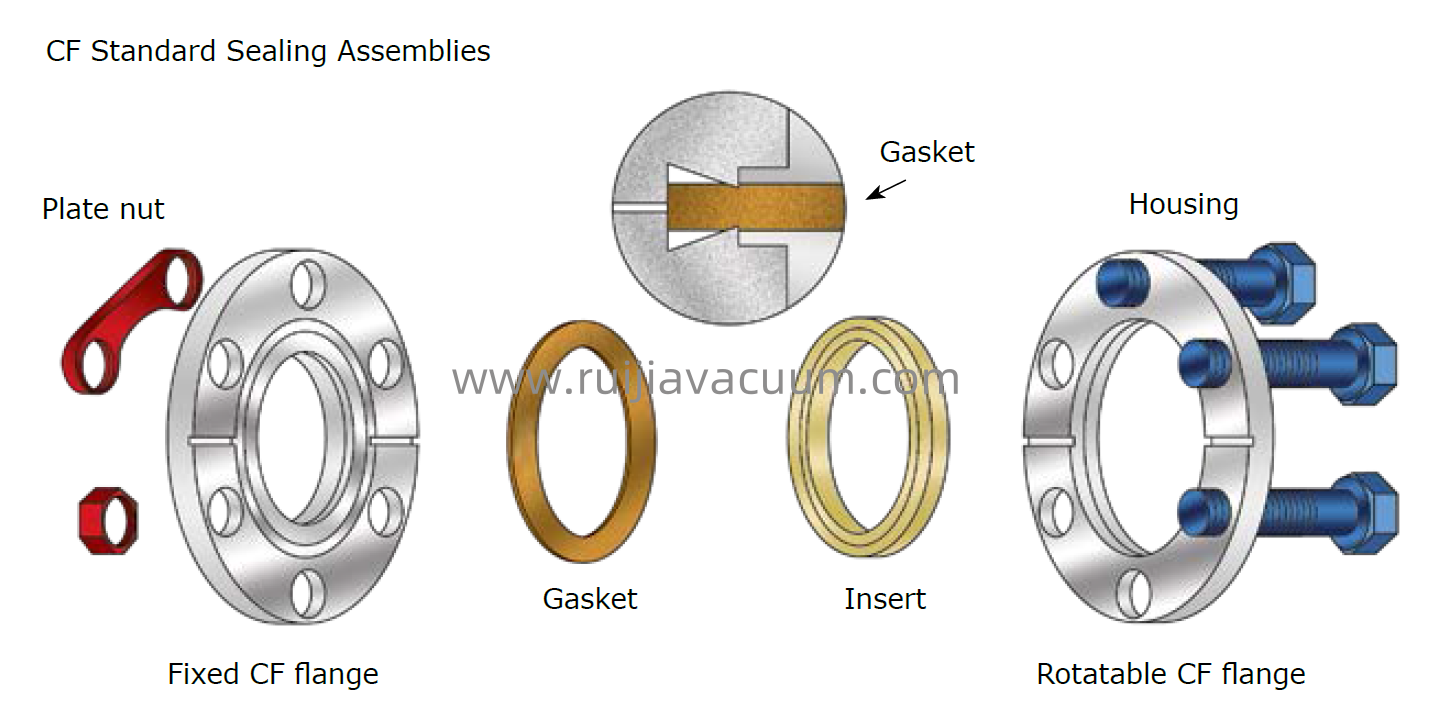

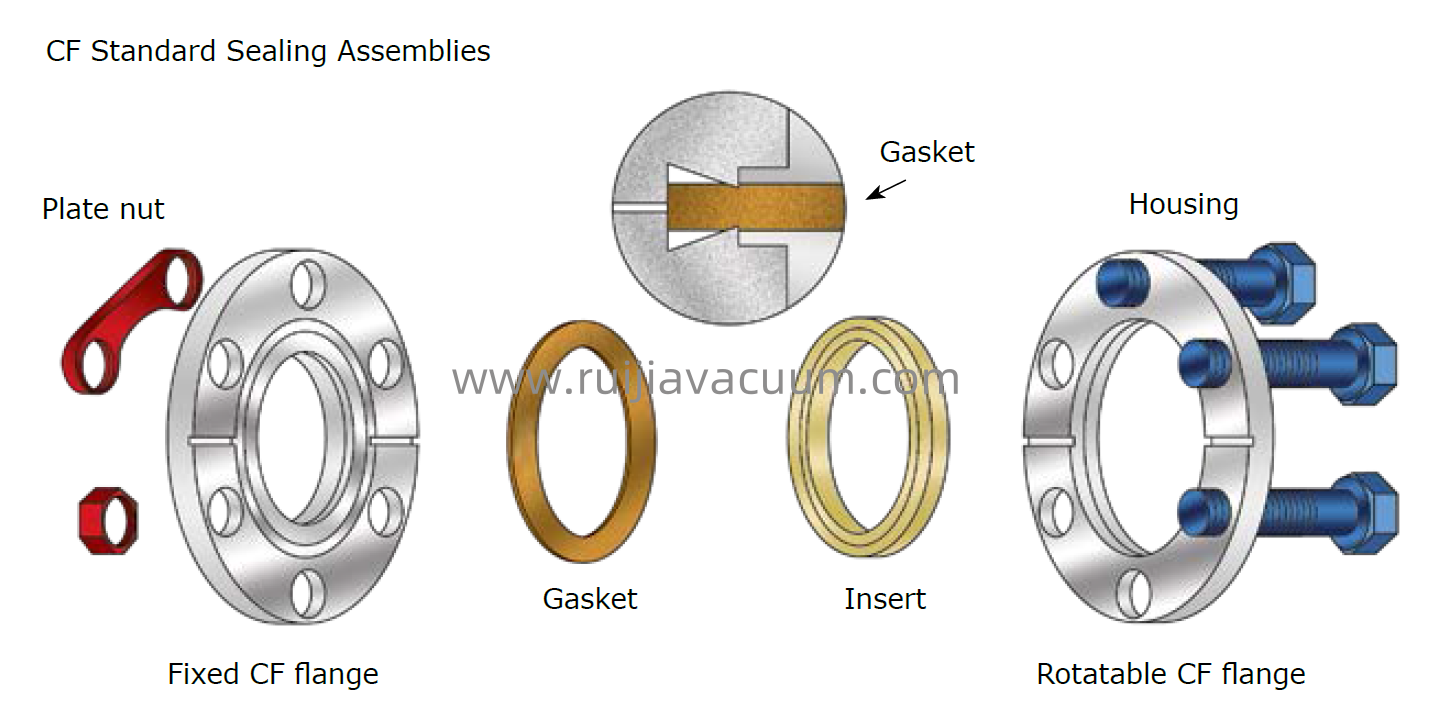

The CF flange system provides a complete range of flanges to mount with tubing sized 6.35mm up to 355mm diameter. The CF seal assembly consists of 3 types of sub-components, two flanges, a sealing gasket and a fastener to compress the seal between the two flanges.

CF Flange Style:

CF Flanges are available in two general styles: fixed and rotatable.

Fixed flanges have a set bolt hole orientation.

Rotatable flanges have a two piece design allowing for bolt hole rotation to ease bolt alignment when mating the two flanges.

The two pieces of the rotatable CF flange are called the insert (in which the knife-edge is machined) and the housing (in which the bolt holes are machined). When installing these components the housing is placed behind the insert on the tubing prior to welding the insert to the tubing.

CF Flanges Feature:

Both fixed and rotatable flanges are available with clearance and tapped bolt holes.

Clearance bolt holes allow for unrestricted passage of a bolt through the flanges. The bolt is then tightened with a nut on one side of the flange assembly. Tapped bolt holes are threaded to receive and tighten the bolt directly and do not utilize a nut. This is an excellent space saving option and is particularly useful when fastening a flange to a chamber wall or gate valve.

CF Flanges Sealing Gaskets:

CF gaskets is made of Oxygen free copper or silver plated copper.copper gaskets are by far the most commonly used with the CF flange system and when compressed between the flange knife-edges provide a vacuum tight seal capable of achieving ultrahigh vacuum pressures and temperatures as high as 450˚C. CF gaskets are reusable and can be used many times to make new vacuum tight seals.

CF Flanges Fasteners:

CF fasteners are bolts, nuts and washers made of high tensile strength stainless steel. Bolts are offered with standard hex-head or 12-point head and silver plated. Kaysen recommends either high temperature anti-seize lubricant or silver plated bolts for applications with high temperature to prevent galling of the bolt and nut or threaded bolt hole. Nuts are offered with standard or plate nut design. Plate nuts are the most convenient way of fastening CF flanges. Plate nuts allow adjacent bolts to be tightened into one nut and eliminate the need for a second spanner to hold the nut while tightening. This is particularly useful when access to the installation is limited.

What can Kaysen do for you?

Kaysen offers a complete line of flanges, fittings, valves, traps and accessories with CF connections that can be used to create a complete vacuum system or pumping line.

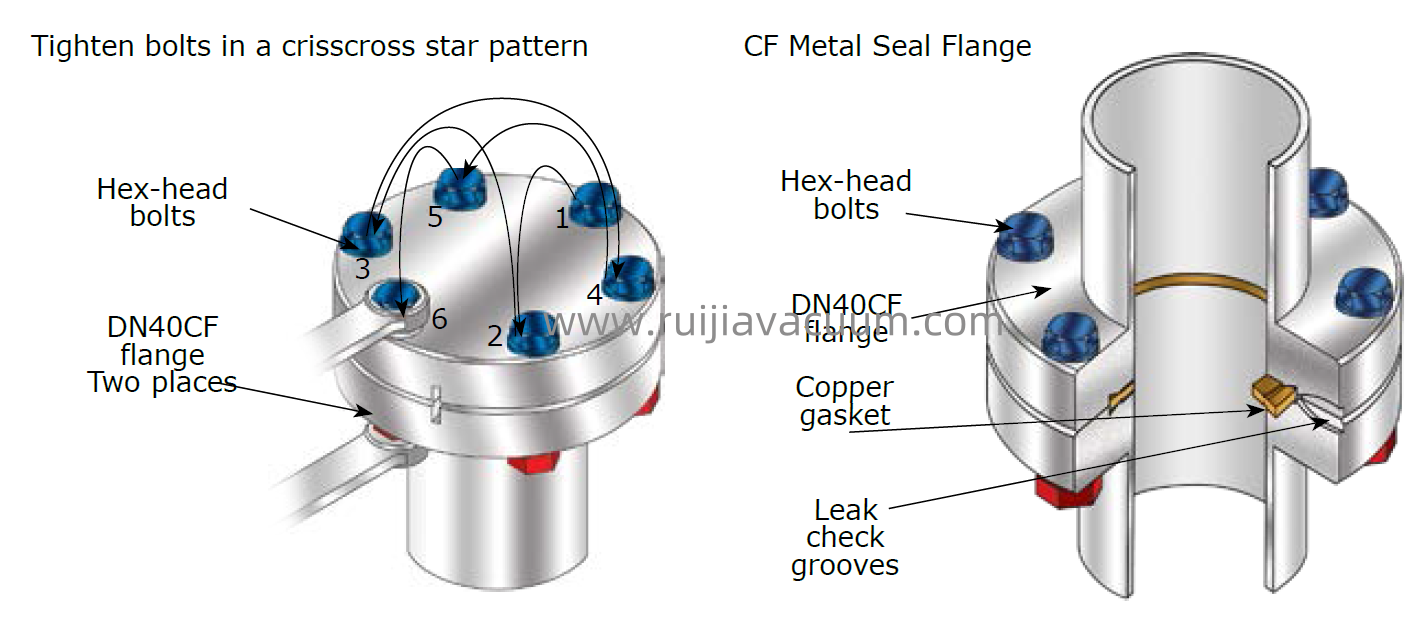

A sealing pair of CF flanges each contains an identical flange face with a knife-edge machined into the surface. A copper sealing gasket is placed into the gasket capture groove of one of the two flanges. The flanges compress the gasket as the fastening bolts are tightened. This pressure forces the knife-edges of the two flanges into the gasket, creating an annular groove. The gasket material cold flows under this pressure and fills microscopic surface imperfections on the sealing knife-edges creating a vacuum tight seal capable of withstanding temperature extremes from –200˚C up to 450˚C and pressures as low as 1x10-13 Torr.

CF Flanges System Assembly Instructions

Always wear gloves (lint free) when touching or handling any part of a vacuum component that will come into contact with the vacuum atmosphere.

Check both flanges for cleanliness and that sealing surfaces have no dents or scratches.

Apply anti-seize lubricant to the threaded portion of your bolts. If you have purchased silver plated bolts then the anti-seize lubricant is unnecessary.

Kaysen recommends either anti-seize lubricant or silver plated bolts for almost all CF assemblies, especially for those assemblies that will be subjected to high temperatures or have tapped bolt holes Bolt galling in a tapped flange can ruin the machined thread pattern in the bolt hole and render the entire flange unusable place a sealing gasket against the knife-edge of a non-rotatable flange.

Align the bolt holes and leak check groove of the opposing flange insert the bolts, add the washer to the nut side of the assembly and hand tighten. After hand tightening all the bolts in the assembly, use a spanner on both the bolt head and the nut. Tighten by turning the nuts in small increments (1/2 turn or less) using an alternating pattern, choosing a bolt across the flange from the last. Continue the incremental tightening of the nuts in the pattern until the desired torque pressures have been achieved. This tightening procedure ensures even gasket compression and a reliable seal.

We're also excited to offer high-quality VACUUM COMPONENTS for all your needs!

With a vast inventory, we ensure prompt delivery. Each CF Flanges fittings is thoroughly inspected, and we include a quality assurance report with every order.

Reach out to us for your VACUUM COMPONENTS requirements!